WHAT IS SMCS

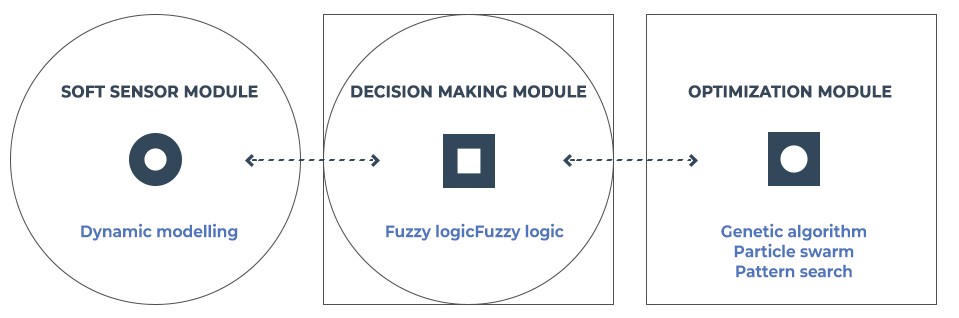

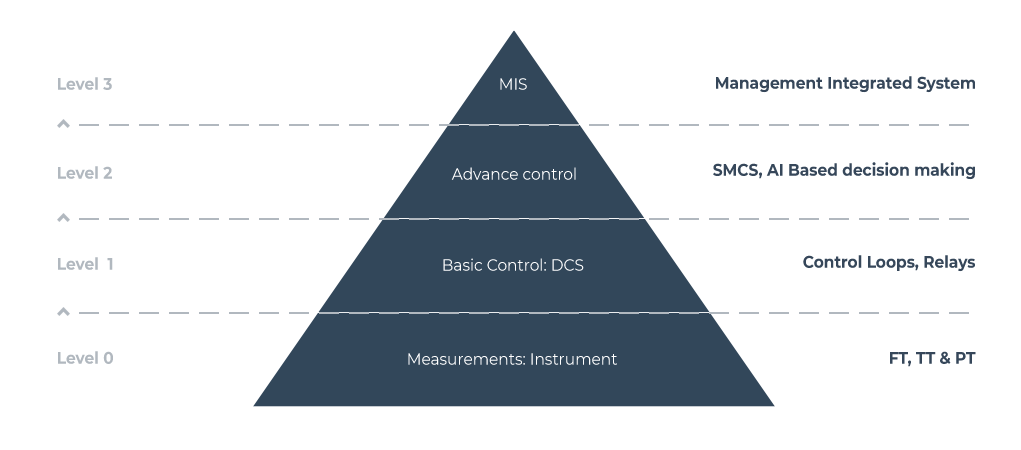

SMCS is an AI based decision making solution in the second level of measurement and control system. As an advance control system, SMCS optimize the process using 3 main modules.

Decision making module which is based on fuzzy logic. Optimization module which uses a combination of genetic algorithm, particle swarm and pattern search and optimizes the framework of decision making module. And as the third module SMCS uses dynamic modelling as a sort of soft sensor to obtain certain information from the grinding process.

Therefore, SMCS is able to reach the optimum process and maintain that level regardless of nonlinear and time-dependent nature of the process.

FEATURES

Adaptive optimization

The AI optimization module ensures that SMCS adapt itself to the condition of grinding circuit. The data will be collected, analysed and run through optimization algorithm and every year client will receive an upgraded version of the software which is more custom made for the client’s grinding circuit characteristic, therefore can reach a better performance

Semi-automated calibration

This features enable more accurate and optimized calibration. The AI technologies and calibration algorithm use the data from the line to ensure the most optimum performance and allows SMCS to create and execut a complex control strategy based on various wishes and needs of customer and griding circuit. Reaching the optimum stand point does not always have a direct path.

Fault detection

Any failure in the field sensors, noisy or disconnections will be detected and notified. Alarms in the SMCS monitor indicates which sensor is faulty. Also critical conditions in SAG/AG includes liner damage condition and overload condition will be detected and the system will take the adequate action to prevent any damage